- Digital Transformation of Industries

- Why Automated industrial inspection (A-II)?

- A-II in Mining Operations

- Signal Processing to improve image data quality

- Deep Learning architectures that can process multimodal data

- Repurposing A-II to detect defects

Digital Transformation of Industries

Digital transformation and automation of traditional industries and manufacturing practices (Industry 4.0) through leveraging Cloud Computing, Industrial IoT, big data analytics, and AI/ML capabilities can increase productivity, improve occupational safety and optimize energy consumption.

Why Automated industrial inspection (A-II)?

Automated industrial inspection (A-II) are computer vision based predictive solutions that are developed by leveraging state-of-art signal processing algorithms and deep learning models. The goal of A-II is to automate industrial inspections, a critical component of Industry 4.0. Such automations enable to not only improve productivity, but also lead to significant improvements in operational safety.

A-II in Mining Operations

Mining is one of the few occupations with high employee risk. For example, in United States with its advanced operational safety had about 12 fatalities in 2019 from coal mining and 15 fatalities from metal/nonmetal mining. I was part of a small team of data scientists who worked with a leading potash mining corporation in North America to automate detection of geological features (clayseam) that can optimize potash extraction. The final solution will result in automous operation of mining machinery that will have a huge impact on the workplace occupational health and safety.

Signal Processing to improve image data quality

Our team adapted and optimized deep learning architectures (Unet family) to perform semantic segmentation. These architectures can help create models that can automatically detect clayseam from the input video signals. However, video signals from underground mining operations suffer from high optical ‘noise’ and poor lighting that degrades the computer-vision’s accuracy. As part of the project, we developed advanced signal processing approaches employing global and local filters in both spatial (ex: histogram equalization) and spectral (ex: FFT transformations) domains to eliminate noise and improve image quality. These improvements in image quality led to a marked improvement in the detection and accuracy with minimal addtion to computational cost.

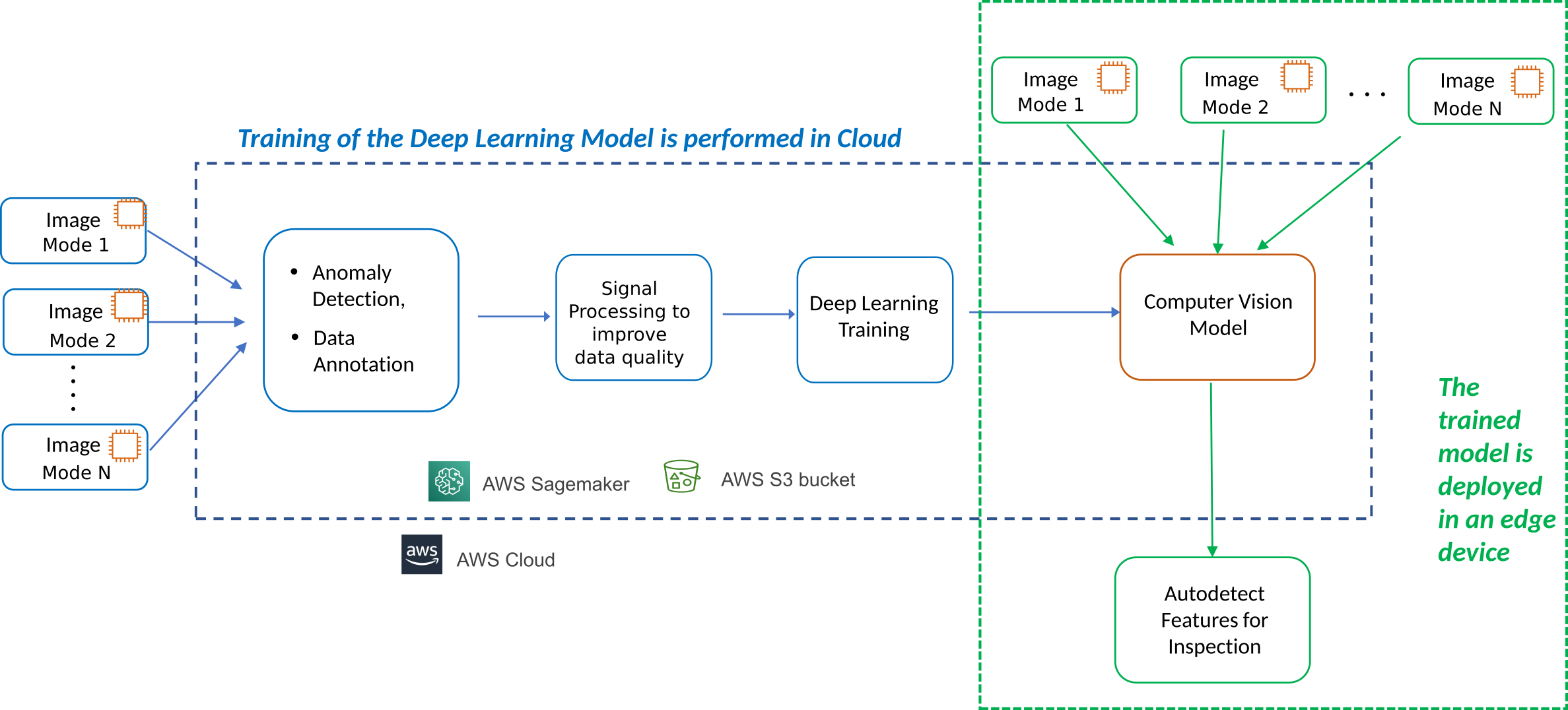

Deep Learning architectures that can process multimodal data

The detection accuracy for the image-processing solution can be further improved if we can augment video signals with other imaging signals such as infrared or LIDAR cameras. As part of this project, we developed a new deep learning-based solution that can simultaneously use data from multiple imaging modes that led to further improvements in detection capabilities. The custom model traning and inference capabilities were built in cloud (AWS) with docker containerization. This in turn, enabled us to rapidly train the model in the cloud and use the same framework to deploy and test the model on edge devices. A template of the architecture used in shown below.

A sample output of the semantic segmentation output from detecting clayseam is shown below where the detected clay seam is highlighted in green.

Repurposing A-II to detect defects

Currently, I’m working along with my team to repurpose this solution along with other components to automatically inspect defects such as cracks, fractures, blockages in wastewater distribution networks for a major customer in North America. A sample detection of cracks and fractures from pipe inspection is shown below.